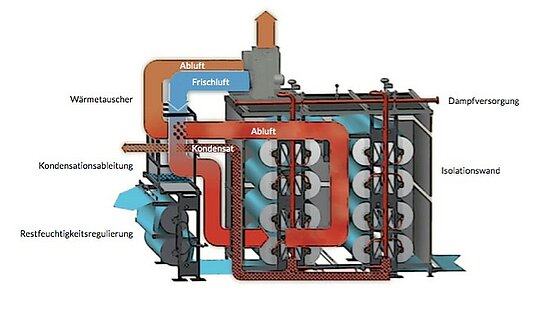

The fresh air supplied is heated in a two-stage heat exchanger system. In the first stage, the energy contained in the exhaust air is used to heat up the supply air. This is done with high efficiency by condensation of the water vapor contained. In the second stage, all of the condensate that accumulates is re-evaporated from the cylinders and now also releases its energy to the preheated fresh air. With the exhaust air humidity control, the system automatically adjusts to the optimal operating point.

With this method it is possible to generate an overall energy balance of the cylinder dryer in which the convection and radiation losses are reduced to the physically achievable minimum.

The system is completed by a continuous adjustment of the drying capacity in connection with a residual moisture control and the recirculation of the cylinder steam with the SteamPlus technology.

The result is an increase in the maximum drying capacity of approx. 10% and an energy saving of at least 20%.