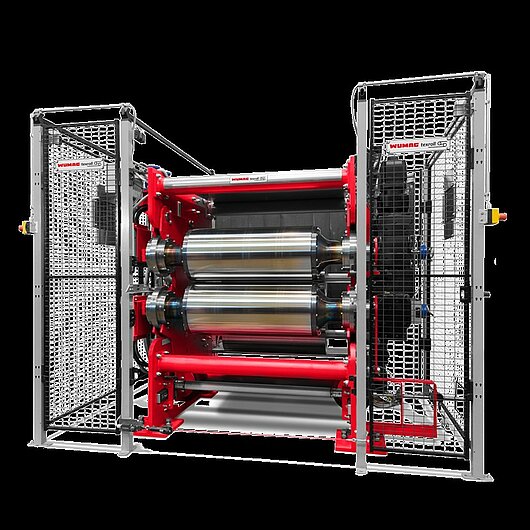

Calender

Non-Woven calender for nonwovens and technical textiles for processing of needled punched nonwovens from:

- PP, PET

- Bico fiber and others

Applications like:

- Geotextile

- Roofing

- Automotive, filters

- Max. Fabric width 7 m

- Max. Temperature 290 ° C

Turn-Key system

Features/Performance:

- Thickness reduction (reduction of transport volume)

- Strength increase in the longitudinal and transverse direction

- Dimensional stabilization

- One or two-sided surface calendaring

Options:

- Horizontal or vertical arrangement of the rollers

- 2 or 3-roller version

- Different product-specific product flows

- Retrofittable chill roll unit

- Nip force up to 100 N/mm

- Hardened rollers (54-58 HRC)

- Embossing rollers can be integrated

- Roll surface with chrome plating or non-stick coatings

- Electromechanical X-crossing

- Electric gap adjustment

- Goods tear sensor and / or metal detector

- Turn-Key system with control cabinet, control Siemens S7-1500

- FI controlled single drives

- Heating/temperature control

The GT 400 Hightemperature Calender

For the thermal treatment of carbon, glass and aramid fibers as well as for high-tech composite materials, it is often necessary to generate particularly high temperatures in the calender.

WUMAG TEXROLL has developed the GT 400 roller systems for these cases.

Direct electrical heating of the steel rollers generates temperatures of 50 - 400 ° C on the roller surface. Individually controlled heating zones ensure a temperature accuracy of +/- 2 ° C across the width and the entire temperature working range.

The modularly constructed calenders of the GT 400 series are fully assembled and can be put into operation at the customer's “plug and play” level.

The hardened and chrome-plated steel rollers are driven in the nip or on the gap. The calenders can be expanded with tempered rolls and winding systems.